#2. 'Scaling down' carbon removal costs

A non-technical primer on how permanent carbon removal can become less expensive and scale from early adoption to mass market.

Removing carbon from the atmosphere is not just tricky but also costly.

What makes it trickier is how quickly the total cost of carbon removal could spiral into a ginormous figure.

On an average we need to remove 10 billion tons of CO2 / year (hit the yearly average number by 2050). Currently it costs an average $300/tCO2e.

This sums up to $3 trillion global spend every year on carbon removal alone.

As the quantity of atmospheric CO2 to be removed is fairly fixed, the only lever left to soften the cost burden is reduce the per ton cost of CO2 removal & storage.

There are great readings here & here, as to why a $100/tCO2e price point is a sweet spot for the CDR markets to take off.

The question is - can all long permanence CDR pathways come down to $100/tCO2e in due course of time ?

How do we think about this problem statement ?

The good way to start is by getting a sense of the baseline - where do current prices stand for different carbon removal methods.

Next, is there a cost curve that emerges for any of these methods.

If not, then what are the typical cost reducing drivers in a frontier tech industry - adapt those to CDR and try to land some sort of cost curve.

This could be good proxy to identify how costs might fall & flatten out for carbon drawdown, as it scales.

The baseline: CDR pricing band

Price of long permanence carbon removal hovers in the range of $1000-$100.

That’s a really wide range, I know.

As, most public announcements regarding carbon removal purchase do not disclose commercials, it’s difficult to get a precise know-how of actual current costs.

However, cdr.fyi came out with their own method of estimating the weighted average price per ton CDR sold - it stands at $403/tCO2e at the end of 2022.

However, there’s large price variance between pathways and even within the same pathway.

For example -

Biochar minimum cost is $11/tCO2e whereas for ocean alkalinity it is stands at $1370/tCO2e !

That’s more than 100x difference.

Similarly, for DAC the spread between min-max is nearly $2000 !

This huge variance is largely driven by a diverse set of approaches, technological maturity, and willingness to sell down the cost curve.

A notable observation from the cdr.fyi data is that based on pricing over time, there is hardly an emergence of a clear cost curve.

With such huge variance in pricing bands, how do we eventually narrow it & brings it down to $100/tCO2e neighborhood.

This is where, there’s merit in identifying cost decrease drivers in historic high tech sectors and adapt them to long permanence CDR tech.

Cost decrease drivers: Arriving at a learning rate for CDR

Long permanent CDR tech, so as to speak, is at a current low technology readiness level (TRL). This is because, mostly they are either in R&D or pilot demonstration phase.

This means there’s a dearth of credible data that comes from their technology learning & experience, that’s often seen at a mature stage of development such as - market formation & full commercialization.

In order to reach the holy grail - $100/tCO2e CAPEX cost, we need to work backwards and see what kind of scale needs to be achieved & how much time it’s going to take.

For that, we need to arrive at the different cost drivers & the rate at which these push the costs, down with scale - finally arriving a scale where we touch $100/tCO2e.

In an earlier essay, Grant Faber outlined different cost decrease drivers that are usually at play as an ‘emerging tech’ progresses through different stages of maturity - research and development, demonstration, market formation, and full commercialization.

Here’s a simple break-up of these cost drivers.

Exogenous cost reducers - cheaper input costs not directly resulting from technology itself but from external factors like - policies favorably impacting supply chain, Government subsidies, cheaper feedstock etc.

However, it is the cost reductions from continued use of a given technology, that moves the needle on scalability.

These are called ‘endogenous cost decrease drivers’.

Endogenous cost decrease happens in three ways -

Learning by searching

Learning by deployment

Economies of scale

Learning by searching is cost reduction due to R&D efforts that lead to cheaper material creation & better process efficiency. As you would have guessed, this is relevant for CDR tech in R&D phase such electrodialysis of ocean water, new desorption technology using metal organic framework etc.

Learning by deployment is where majority of cost reduction in long CDR tech can be achieved. These are the cost reductions as a result of experience gained during actual project development. CDR methods in pilot or market formation stages can only uncover cost benefits not through lab experiments but by deploying more & more projects. This happens mostly due to process standardization, better trained models to measure carbon captures, reduced operating times due to trial & error and automation.

Economies of scale is where cost reduction happens due to volume discounts, lower fixed costs per unit of production volumes and cheaper financing due to larger operations. These cost reductions can be seen in mass manufacturing of IC chips, solar PV modules, automobiles etc.

While these cost reductions don’t happen in silos, a good way map them to long permanence removal scales would be:

0 to 100s ton: Cost reduction due to learning by search (LBS)

100s to kiloton: Cost reduction due to learning by deployment (LBD)

Kiloton to megaton: Cost reduction due to economies of scale (EOS) & learning by deployment (LBD)

For majority of CDR methods, learning by doing is the primary cost decrease driver - costs go down, as deployment scale goes up.

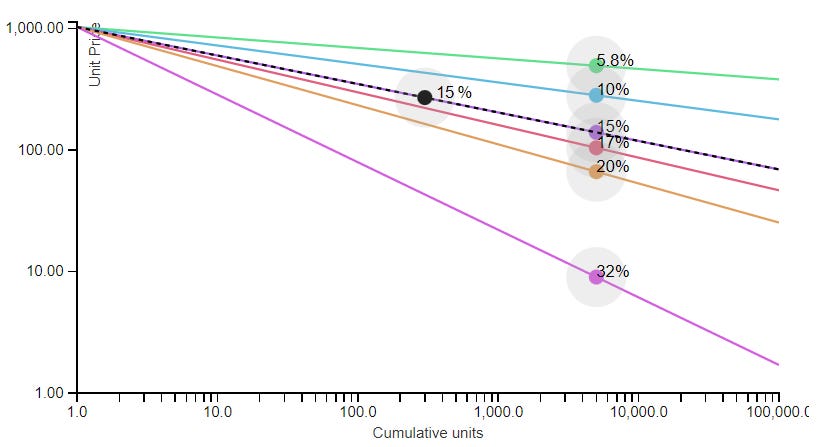

This decrease in unit price for a doubling in the cumulative volume of technology deployment is called learning rate.

For example if a technology gets 20% cheaper every time we double the cumulative volume of units made, then it has a learning rate of 20%.

Given the fact that CDR methodologies are so nascent, that even a basic learning curve hasn’t emerged. This means, we cannot make any actual projections of what will be the learning rate for different long CDR methods.

Nevertheless, we can use learning rate arrived by (Rubin et al. 2006) for CCS as a good proxy.

Rubin measured learning rates for Flue gas desulphurization, selective catalytic reduction, LNG production, hydrogen production and other industrial processes - to land at a learning rate range of 12%-20% for CCS.

Thus for long permanence CDR we can assume an average learning rate of 15%.

For CDR methods that are still in lab stage, learning rate would be much lower. However for kiloton scale, we can safely assume 15% learning rate through learning by deployment.

Assuming current unit costs of $400/tCO2e after 37,000 tons/year removal (refer to 2022 Carbon Removal Market Overview) at a 15% learning rate, we will have to remove nearly 14 million tons of carbon to reach the price point of $100/tCO2e.

Which means a project developers must scale to 14 projects each of 1 million tons/year removal in order to hit the price point that appeals to large corporate buyers.

While this is a very high level ball-park calculation - it gives a sense of scale that we need to achieve for any given CDR method to cross the viability chasm.

Getting to $100 per ton for permanent CDR

Actual tons of carbon removed has grown by more than 200% year on year between 2020 and 2022 - going from 6.9k tons (2020) to 36.8k tons (2022). Despite this undeniable momentum in growth, long permanence CDR is still in early adoption stage.

To hit mass adoption, CDR credits need a second wave of corporate & public institutional buyers.

At a policy level, this would require modifying SBTi to incentivize carbon removal credits and signal the difference between “avoidance based carbon offsets” and “long permanence carbon removals”.

At a market level, project developers should double-down on building reliable monitoring, reporting & verification (MRV) methods. Especially for open system pathways like Enhanced Weathering, Carbon Mineralization - where it is impossible to directly measure the amount of actual carbon captured.

Very interestingly, 3rd party registries & marketplaces like Verra and Puro are already working towards building carbon removal verification standards for different CDR pathways. This will help in issuance of trust-worthy removal based credits to corporate buyers.

With these developments, we can hope to see more corporate buyers join the list of top 16 companies that purchased 1000+ tons of removals in 2022 - eventually building up to mass adoption to hit that $100/tCO2e price target.

Found this article interesting ?!

Resources:

https://cepe.ethz.ch/content/dam/ethz/special-interest/mtec/cepe/cepe-dam/documents/education/selected-term-papers/Micek.pdf

https://www.cmu.edu/epp/iecm/rubin/PDF%20files/2014/Reducing%20the%20Cost%20of%20CCS%20through%20Learning%20by%20Doing.pdf

https://7518557.fs1.hubspotusercontent-na1.net/hubfs/7518557/Supplier%20Documents/v0.9%20ERW%20Draft%2029th%20September.pdf

Why are so few companies purchasing removals at scale, and how can that be changed?

https://frontierclimate.com/writing/quantifying-delivered-cdr